Advantages

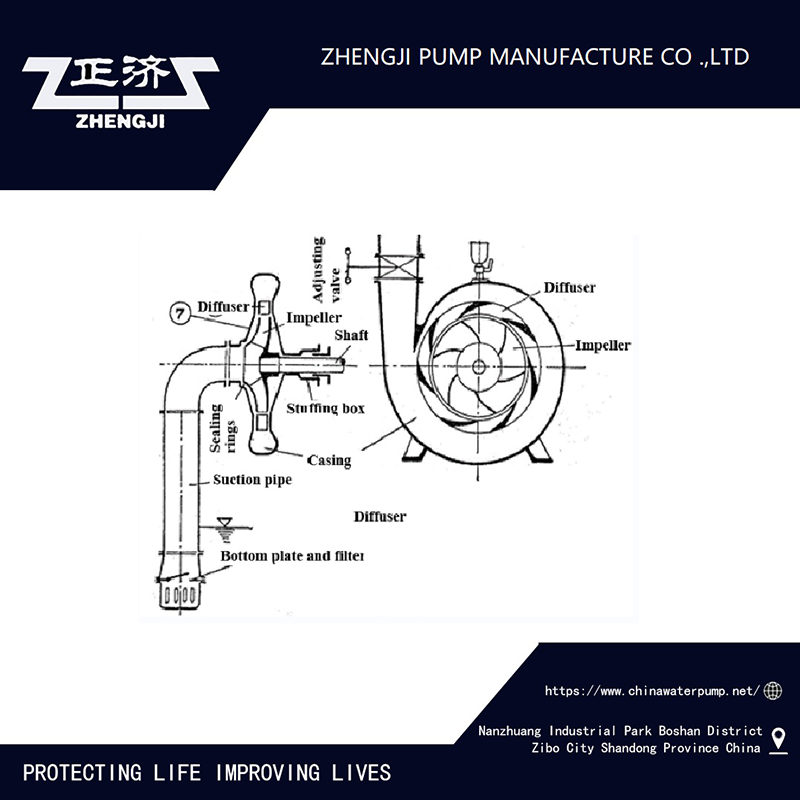

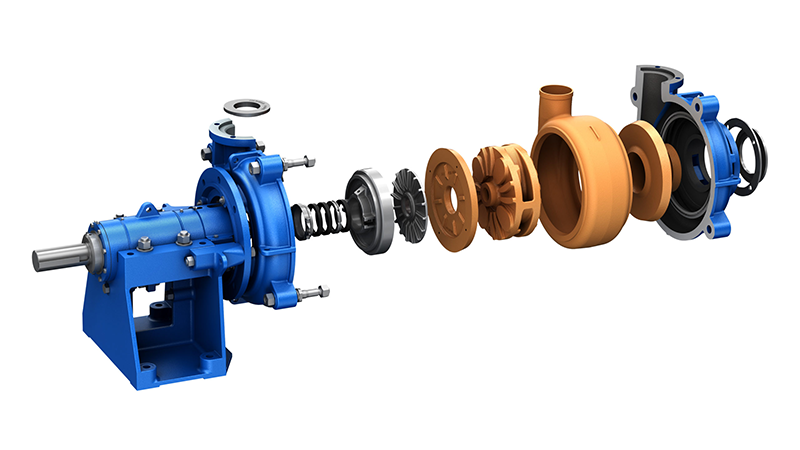

Slurry pump adopts high chromium alloy wear-resistant material combined with advanced wear-resistant alloy smelting technology, casting process and heat treatment process to ensure the surface of the casting smooth, the internal organization of the casting precision, reliable quality. The precision and service life of wear-resistant castings are greatly improved.

characteristic

Full model, stable performance, wide coverage conditions, convenient selection and so on.

The slurry pump has innovation in hydraulic design, structural design and other aspects. The flow parts are made of self-developed high chromium wear resistant alloy with high efficiency, energy saving, long service life, light weight, reasonable structure, reliable operation, low vibration, low noise, easy maintenance and other remarkable characteristics.

Double pump shell structure, easy to replace the flow parts, according to the pressure needs of the outer pump shell with ball wear cast iron, the inner shell with high chromium anti-wear discount cast iron or cast steel.

Application

Slurry pumps are widely used in electric power, metallurgy, coal, building materials, chemicals and other industries, mainly used to transport abrasive slurry containing solid particles, such as concentrate tailings processing plant, power plant ash removal, coal preparation plant transport slime and heavy medium coal separation, coastal river mining operations transport slurry. The maximum weight concentration it can handle is: 45% mortar, 60% pulp, according to customer needs can be run in series.

Seal

The slurry pump can adopt the auxiliary impeller packing combined seal and mechanical seal two kinds of seal form. The outlet position of the pump can be installed and used according to the need to rotate eight different angles at a 45 degree interval.

![[field:text/]](/uploads/231017/2-23101G51642321.jpg)

![[field:text/]](/uploads/231017/2-23101G51642321.jpg)

Our company specializes in the design, development, manufacture and sale of universal fluid equipment pump manufacturers.

Our company specializes in the design, development, manufacture and sale of universal fluid equipment pump manufacturers.

Nanzhuang Industrial Park Boshan District Zibo City Shandong Province China

Nanzhuang Industrial Park Boshan District Zibo City Shandong Province China

zhengji@zhengjipump.com

zhengji@zhengjipump.com

+86-533-4505770

+86-533-4505770

+86-533-4518770

+86-533-4518770

+86-13805334487

+86-13805334487